Understanding the inner workings of a vehicle's fuel system is crucial for anyone interested in automotive technology. One of the key components that often goes unnoticed is the fuel pressure regulator. This device plays a vital role in maintaining the correct fuel pressure within the fuel system, which is essential for optimal engine performance. Without a properly functioning fuel pressure regulator, your engine could face a range of issues, from poor fuel efficiency to hesitation during acceleration.

In this comprehensive overview, we will delve into the mechanics of fuel pressure regulators, exploring how they operate and why they are indispensable in modern fuel systems. Whether you are a car enthusiast looking to expand your knowledge or a mechanic seeking to refine your skills, understanding fuel pressure regulators will enhance your appreciation of automotive engineering. Join us as we break down the principles behind this critical component and its impact on vehicle performance.

What is a Fuel Pressure Regulator?

A fuel pressure regulator is a crucial component in an internal combustion engine's fuel injection system. Its primary function is to maintain a consistent fuel pressure within the fuel rail, ensuring that the engine receives the correct amount of fuel for optimal performance. By regulating the pressure, the fuel pressure regulator helps to achieve the right air-fuel mixture, which is essential for efficient combustion and reduced emissions.

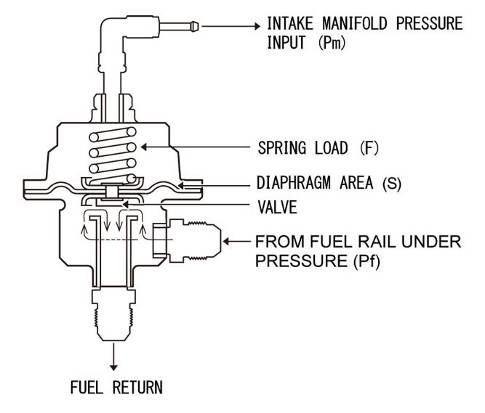

The design of a fuel pressure regulator typically includes a diaphragm, spring, and a return line to the fuel tank. The diaphragm reacts to changes in fuel pressure, while the spring provides the necessary resistance to maintain the desired pressure level. When the fuel pressure exceeds the setpoint, the regulator opens the return line to relieve excess fuel, maintaining stability in the system.

Proper functioning of a fuel pressure regulator is vital for engine performance. If the regulator fails or becomes faulty, it can lead to symptoms such as hard starting, poor acceleration, or even engine stalling. Therefore, understanding how fuel pressure regulators work and recognizing their importance can help in diagnosing fuel-related issues in vehicles.

How Fuel Pressure Regulators Work

Fuel pressure regulators play a critical role in managing the fuel delivery system of an internal combustion engine. Their primary function is to maintain a consistent fuel pressure within the fuel rail, ensuring that the fuel injector operates effectively. The regulator adjusts the fuel pressure based on the engine's demand for fuel, which varies with throttle position and engine load. It monitors the pressure in the fuel rail and opens or closes a return line to regulate excess fuel back to the tank, thus maintaining optimal pressure.

The operation of a fuel pressure regulator is often based on a diaphragm mechanism. When fuel pressure exceeds the set value, the diaphragm moves to open a valve leading to the fuel return line. This allows excess fuel to flow back to the tank, reducing pressure in the rail. Conversely, if the pressure drops below the desired level, the diaphragm will close the return path and maintain pressure by restricting the fuel flow. This dynamic adjustment of fuel pressure is crucial for ensuring that the engine receives the correct amount of fuel for efficient combustion.

Additionally, fuel pressure regulators can be influenced by various factors, such as vacuum levels in the intake manifold. In engine designs featuring vacuum-operated regulators, the intake manifold vacuum provides additional control by reducing the spring pressure on the regulator diaphragm. This allows the regulator to adjust fuel pressure automatically in response to engine load, optimizing performance and fuel efficiency. Through this intelligent modulation, fuel pressure regulators contribute significantly to the overall effectiveness of the fuel delivery system.

Common Issues and Solutions

Fuel pressure regulators can experience various issues that can impact engine performance. One common problem is a clogged or blocked regulator, which can prevent adequate fuel flow and lead to engine stalling or poor acceleration. To resolve this issue, it is crucial to clean or replace the regulator, ensuring that fuel can pass through it properly. Regular maintenance checks can help catch this problem early.

Another frequent issue is leaks around the regulator seal, which can lead to fuel pressure drops and increased fuel consumption. This leakage can also pose safety risks due to the flammable nature of gasoline. To fix a leaking regulator, inspection for cracks or worn seals is necessary, and replacing any damaged components will restore proper function and prevent further issues.

Lastly, improper fuel pressure readings due to a failing regulator can result in poor engine performance and increased emissions. If the regulator is not maintaining the correct pressure, it is essential to test the fuel pressure with a gauge and compare the readings to the manufacturer's specifications. If the reading is off, replacing the regulator is the most effective solution to ensure the engine runs optimally.